打开文本图片集

摘要:挠性接头角刚度的测量精度直接关系到陀螺仪的控制精度和灵敏度,但传统方法存在较多问题。根据挠性接头角刚度静态测量原理,基于不同的加载方式提出2种角刚度静态测量方法,即机械式加载角刚度测量和压电式加载角刚度测量。搭建以电动倾斜台为分度加载驱动的机械式挠性接头角刚度测量系统,进行挠性接头角刚度测试试验,得出挠性接头角刚度数值。针对机械式加载测量方法中测试结果不稳定的问题,设计利用压电促动器的静态加载机构,提出了一种利用压电促动器测量挠性接头角刚度的方法。使用ANSYS Workbench对压电加载机构位移输出进行仿真,位移输出满足挠性接头角刚度静态测试加载要求,验证了压电式静态测量方法理论的可行性。

关键词:精密仪器制造;挠性接头;压电促动器;角刚度;静态测试;放大机构

中图分类号:TH703文献标志码:A

Abstract:Measurement accuracy of the angular stiffness of flexible joint is directly related to the control accuracy and sensitivity of gyro, but the traditional measurement methods have many problems. According to the principle of angular stiffness measurement of flexible joint, two static measurement methods of angular stiffness are proposed based on different loading ways, namely mechanical loading angular stiffness measurement and piezoelectric loading angular stiffness measurement. The mechanical loading angular stiffness measurement system is built by using a motor driven indexing feeding tilting table, the measure experiment if the angular stiffness of flexible joint is conducted, and the angular stiffness of flexible joint is measured. For the excessive fluctuation problem of the measure result in mechanical load test, a piezoelectric loading structure is designed and a measurement method employing piezoelectric actuator is proposed for angular stiffness measurement of flexible joint. Based on ANSYS Workbench, the displacement output of the piezoelectric loading structure is analyzed by simulations. The simulation results illustrate that the displacement output meets the requirement of static loading angular stiffness measurement of flexible joint, and the theoretical feasibility of piezoelectric loading angular stiffness measurement method is validated.

Keywords:precision instrument manufacture; flexible joint; piezoelectric actuator; angular stiffness; static measurement; amplifying mechanism

动力调谐陀螺仪作为一种传感器,广泛用于运载火箭、导弹等的导航系统,其内部弹性元件(挠性接头)的角刚度,作为补偿力矩关键因素直接关系到整个陀螺仪的控制精度和灵敏度[14]。因此,研制挠性接头角刚度测量系统对挠性接头批量化生产非常必要[5]。

目前,挠性接头角刚度的检测仍然以手工吊砝码法为主,这种方法存在效率差、重复度低等问题[67]。利用机械式电动倾斜台对挠性接头进行自动加载,能够解决这一问题。但由于机械式倾斜台位移机构存在爬行现象、机械摩擦和装配间隙等不利因素,影响其定位分辨力和运动精度,造成挠性接头角刚度测量设备实际测试结果稳定性不高、易受环境影响等问题。为解决这一实际问题,需对测试设备分度加载机构进行改进。

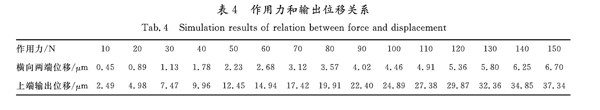

压电陶瓷叠堆执行器利用压电材料的逆压电效应,能够在电压作用下产生成比例的位移和力输出,具有位移精度和分辨率高、响应快、功耗小、无噪声、刚度高等优点,在精密定位、振动控制等领域有着广泛的应用[89]。本文利用压电促动器作为分度加载驱动,提出一种挠性接头静态角刚度测量方法,解决挠性接头角刚度测试稳定性差的问题。使用ANSYS workbench对压电分度加载机构几何模型进行有限元分析,仿真该结构在给定外加载荷的情况下对其产生的影响[1011]。仿真结果验证了压电式静态测量方法理论的可行性,位移输出满足挠性接头静态测试加载要求。

扩展阅读文章

推荐阅读文章

花田文秘网 https://www.huatianclub.com

Copyright © 2002-2018 . 花田文秘网 版权所有