打开文本图片集

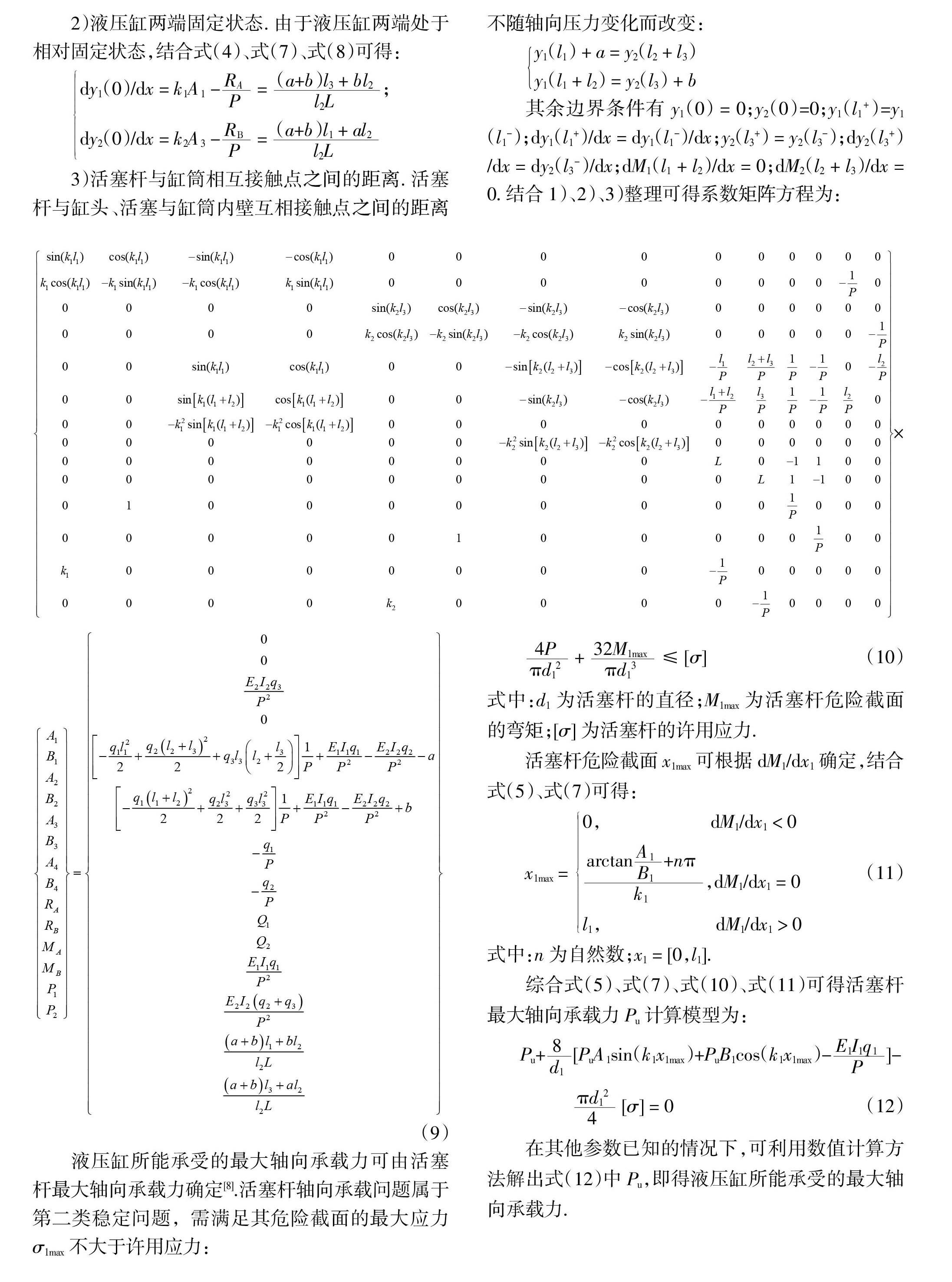

摘 要:综合两端摩擦、配合间隙和自重等因素影响,建立液压缸最大轴向承载力理论计算模型,研究了两端摩擦对轴向承载能力的影响规律,并借助有限元软件ANSYS模拟仿真,最后利用相关试验数据进行验证.结果表明:所建立理论模型计算的最大轴向承载力与试验测试结果误差为13.5%,该理论模型是可信的;随着活塞杆、缸筒长径比减小或摩擦因数增大,液压缸最大轴向承载力增加,但是过大的摩擦因数会改变液压缸两端的连接状态,使其由滑动状态转变为相对固定状态,进而导致轴向承载能力突然增大;随着活塞杆、缸筒长度的减小或活塞杆直径的增大,摩擦对轴向承载能力的影响增强,但缸筒内外径改变时摩擦对承载能力的影响基本不变. 研究结果可为液压缸的设计及性能校核提供重要的参考依据.

关键词:液压缸;承载能力;摩擦;影响规律

中图分类号:TH137;TP391 文献标志码:A

Research on Bearing Capacity of Hydraulic Cylinder

and Effect of Frictions Existing on Both Ends

LI Wei1?覮,WEI Xiaohong1,2,ZHOU Zhixiong1,CHEN Weiguang3

(1. College of Mechanical and Vehicle Engineering,Hunan University,Changsha 410082,China;

2. Troops 95039 of PLA,Shantou 515000,China;

3. Weiguang Hydraulic Cylinder Co,Ltd,Shaoguan 512000,China)

Abstract:Synthetically considering the effects of friction, fit clearance and weight, this study established the theoretical calculation model for the maximum axial bearing capacity of hydraulic cylinders. The influence rule of the frictions at two ends on the axial bearing capacity was studied. It was also simulated by finite element software, which was finally verified by related test data. The results show that the maximum axial bearing capacity calculated by the established theoretical model, compared with the test value, has an error of 13.5%, which indicates that the established theoretical model is reliable. The maximum axial bearing capacity increases with the decrease of the length-to-diameter ratios of piston rod and cylinder, or the increase of friction coefficient. However, excessive friction changes the connection state of the two ends of the hydraulic cylinder, which converts slide state to fixed state and results in abrupt increase of axial bearing capacity. With the decrease of the piston rod and cylinder lengths, or the increase of the piston rod diameter, the impact of friction on the axial bearing capacity increases. However, when the cylinder barrel diameter changes, the impact of friction on the bearing capacity is not changed. This research can provide important reference for the design and performance verification of hydraulic cylinder.

Key words:hydraulic cylinder;bearing capacity;friction;influence rule

液壓缸传递效率高、工作可靠,普遍应用于各种机械设备,对国民经济的发展起着非常重要的作用. 轴向承载能力是液压缸性能的关键指标,直接决定着液压缸的应用场合.而两端摩擦对承载性能有很大的影响,但在实际工程设计校核过程中,该摩擦的影响往往被忽略,这就导致所估算的最大承载能力与实际性能有较大差异.

扩展阅读文章

推荐阅读文章

花田文秘网 https://www.huatianclub.com

Copyright © 2002-2018 . 花田文秘网 版权所有